RODUCTS

-

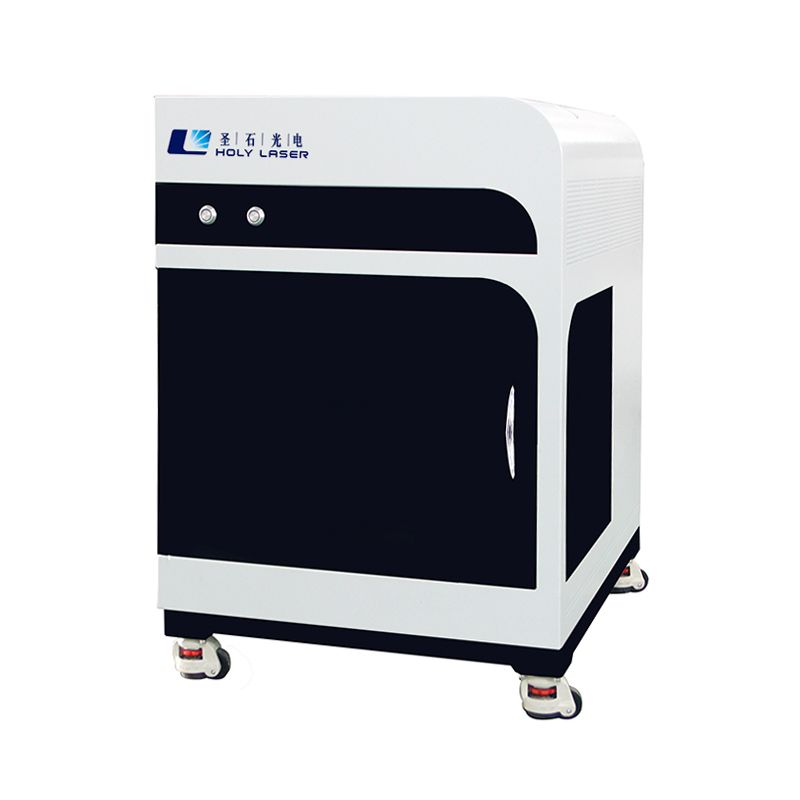

Large format glass laser engraving machine

Large format glass laser engraving machine -

Crystal light ball laser engraving machine

Crystal light ball laser engraving machine -

Crystal laser engraving machine-5KB

Crystal laser engraving machine-5KB -

Photosphere laser engraving machine

Photosphere laser engraving machine -

Large format glass laser engraving machine

Large format glass laser engraving machine -

Large format glass laser engraving machine

Large format glass laser engraving machine -

Glass laser drilling

Glass laser drilling -

Laser welding machine

Laser welding machine -

Laser welding machine

Laser welding machine

WHY CHOOSE US?

Let you enjoy more peace of mind, peace of mind, peace of mind, and considerate products and services

Company Profile

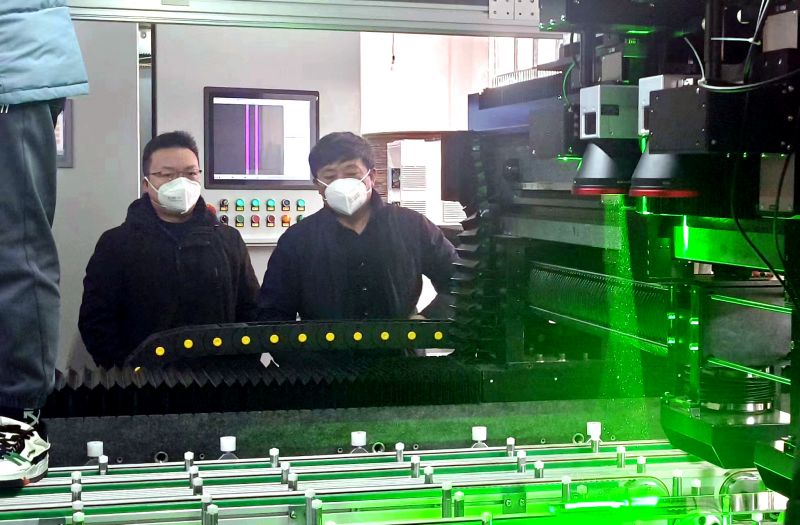

Zhejiang holy Laser Technology Co.,Ltd.founded in 2006, 2021 became a subsidiary of Zhejiang holy Optoelectronics Co., Ltd, headquartered in China (Zhejiang) Pilot Free Trade Zone Yiwu City, Choujiang Street, No. E21, Xinke Road (Science and Technology Industrial Park), Block 2, Area B, and has offices in many parts of the country, and also has an independent overseas business unit. Holy Laser is a national high-tech enterprise specializing in industrial laser intelligent manufacturing, with leading technologies with independent intellectual property rights in laser precision processing, ultra-fast laser micromachining and robot automation. As of 2024, the company has obtained 16 invention patents, 15 computer software copyrights, 38 utility model patents, 18 design patents, the first set of projects in Zhejiang Province rewarded enterprises (automotive rearview mirror glass cutting production line, automotive glass film removal production line).The company's products have been widely used in 3C industry, automotive glass, high-speed rail glass, LED industry, military and automotive power battery, photovoltaic and other new energy industries. The products have been comprehensively promoted around the world, recognized and supported by the majority of users, exported to the United States, Japan, Germany, covering more than 90 countries and regions around the world. Domestic customers include Huawei, Foxconn, Fuyao Glass, Saint-Gobain (China), DMREGC, BOE HC SemiTek Corporation, Suzhou Lanto Electronic Ltd., TM Group, Tsinghua University, Wuhan University, Xi'an Jiaotong University, CHINA DATANG CORPORATION and many other listed companies and institutions of higher learning, for which the company provides self-developed products and technical services, and has formed a long-term and stable strategic cooperative relationship.Holy Laser is the construction unit of "National Thousand Talents Program - Yiwu Laser Industrial Park", and a leading high-tech enterprise supported by Yiwu Strategic Emerging Industry Policy. Since its inception, the community's support and encouragement, the former Vice Chairman of the National People's Congress (Chinese Academy of Sciences) Lu Yongxiang, Zhejiang Provincial Science and Technology Department, the Department of Finance, Secretary of the Municipal Party Committee of Jinhua City, Yiwu Municipal Party Committee, the mayor of the book, and the Ukrainian National Academy of Engineering Sciences, Volodymyr Kovalenko, and other leaders at all levels of leadership and experts have visited the company to guide the work.Holy laser to excellent product quality as a prerequisite, efficient and caring service for the purpose of striving to achieve peace of mind, reassurance, saving, caring customers four-star good enterprise, so that the world fell in love with Made in Zhejiang.The company adheres to the "cultivation, innovation, quality, service" craftsmanship, is committed to creating green, environmentally friendly, energy-saving first-class high-tech products.

Holy Stone LaserYears of industry experience

Win customer satisfaction with qualityTEL:+86-15607066756

ase

+86-15607066756

-

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round.

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round. -

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round.

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round. -

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round.

Customer caseHoly Stone Laser's customers are all excellent customers, and we have a good reputation for cooperating with us all year round.

-

Glass with its transparent, high visible light transmission, high hardness, wear resistance, light weight and other excellent performance has been widely used in building doors and windows, skylights, curtain walls and other parts, to provide landscape, decoration, daylighting and solar radiation energy for buildings, become the main building indispensable materials; Glass is also an important raw material for the automobile, aircraft, ship and other transportation industries, high-tech industries and many other economic sectors. Some scholars predict that new and better materials will not replace it for a long time to come.However, glass also has some defects, such as poor thermal insulation, sound insulation, brittleness and low impact strength, which can not meet the requirements of energy-saving, sound insulation, safety and other higher functions of modern buildings, affect its use in various fields. In order to meet the demand, on the basis of keeping the original excellent properties of glass, the secondary technical processing is carried out to change the original defects, endowed with its new heat insulation, thermal insulation, sound insulation, conductivity, anti-electromagnetic wave, anti-infrared, anti-ultraviolet radiation and other excellent performance, improve its impact strength and decorative functions, so that glass in modern industry, construction industry, high-tech fields and various fields of national economy has been more extensive application.Glass secondary processing technology products are coated glass, insulating glass, laminated glass, toughened glass, thermal bending glass and many other kinds. Processing glass technology in our country from the 20th century 50's began a large-scale research and development, followed by industrial production, almost all kinds of processed glass products are produced in our country, processed glass now our country accounts for about 25% of the total plate glass. From the quantity, variety, quality, production technology and developed countries compared with a large gap (developed countries processing glass accounted for about 70% of the total plate glass) . This situation can not meet the needs of our economic development, which requires us from processing glass production technology research, product variety development, production equipment development, processing glass product application range, in order to promote and promote the development of glass deep-processing technology and the production and application of glass products, we will make greater contributions to the development of new technologies and the national economy.

Glass with its transparent, high visible light transmission, high hardness, wear resistance, light weight and other excellent performance has been widely used in building doors and windows, skylights, curtain walls and other parts, to provide landscape, decoration, daylighting and solar radiation energy for buildings, become the main building indispensable materials; Glass is also an important raw material for the automobile, aircraft, ship and other transportation industries, high-tech industries and many other economic sectors. Some scholars predict that new and better materials will not replace it for a long time to come.However, glass also has some defects, such as poor thermal insulation, sound insulation, brittleness and low impact strength, which can not meet the requirements of energy-saving, sound insulation, safety and other higher functions of modern buildings, affect its use in various fields. In order to meet the demand, on the basis of keeping the original excellent properties of glass, the secondary technical processing is carried out to change the original defects, endowed with its new heat insulation, thermal insulation, sound insulation, conductivity, anti-electromagnetic wave, anti-infrared, anti-ultraviolet radiation and other excellent performance, improve its impact strength and decorative functions, so that glass in modern industry, construction industry, high-tech fields and various fields of national economy has been more extensive application.Glass secondary processing technology products are coated glass, insulating glass, laminated glass, toughened glass, thermal bending glass and many other kinds. Processing glass technology in our country from the 20th century 50's began a large-scale research and development, followed by industrial production, almost all kinds of processed glass products are produced in our country, processed glass now our country accounts for about 25% of the total plate glass. From the quantity, variety, quality, production technology and developed countries compared with a large gap (developed countries processing glass accounted for about 70% of the total plate glass) . This situation can not meet the needs of our economic development, which requires us from processing glass production technology research, product variety development, production equipment development, processing glass product application range, in order to promote and promote the development of glass deep-processing technology and the production and application of glass products, we will make greater contributions to the development of new technologies and the national economy. -

The application scope of laser film removal equipmentCurrently, the most widely used film removal method on the market is to use the film removal wheel to mechanically remove film from the glass surface. However, research shows that the film removal process using removal wheel will directly affect the effect of Low-E glass, thereby affecting the hollow The service life of glass. This film removal process requires the use of a film removal machine and a film removal wheel. The coating layer on the surface is removed through the friction of the film removal wheel on the glass. The parameter settings of the film removal machine and the performance of the film removal wheel itself will all affect Regarding the film removal effect, the equipment parameters can be adjusted according to actual use, and the characteristics of the film removal wheel itself are more important.It can be applied to all touch screen materials, such as ITO, low-e, HUD, etc. So can be used for etching of thermally conductive film, anti-UV film, thermal insulation film, head-up display, sensor wiper and GPS, ETC signal transmission area and other coated glass.

-

Aitomtive giass removal autimationAt present, only the laser film removal equipment developed by Holy Laser is recognized by the market in China. From the development of a single-head infrared laser film removal equipment in 2016, to the development of a 3D curved surface laser film removal equipment in 2023, its competing products are benchmarked against the German 4jet Laser film removal equipment. Holy Stone Laser's products integrate multi-disciplinary technologies such as optical design, laser technology, optical detection, automatic control, structural design, complex calibration, and digital communication technology. Among them, the picosecond laser has complex design, engineering volume and difficulty Large, its core technology is currently only mastered by a few countries such as the United States, Germany, and Austria. At the same time, compared with the equipment of the German 4jet company, our company is more cost-effective, more operable, and constantly iteratively updates the technology.With the gradual popularization of coated glass, it will replace the traditional glass + film combination mode in the future, and the coated glass etching products will usher in the performance explosion period.

Industry news

Industry news